With an annual sawing capacity of half a million cubic meters and deliveries to over 30 countries, there is no room for compromise when it comes to technology. Westas Group is one of Finland’s largest private sawmill companies, with operations built on high quality and responsibility.

Westas recently observed that their existing board scanners were reaching the end of their lifecycle. As production volumes grew, the company needed a partner capable of providing next-generation solutions to ensure long-term competitiveness. The choice was Finnos.

Speed and Flexibility Were Key

Westas’ Quality Manager, Jarmo Joki, emphasizes that in addition to the technology itself, trust and service capability played a major role in the decision-making process.

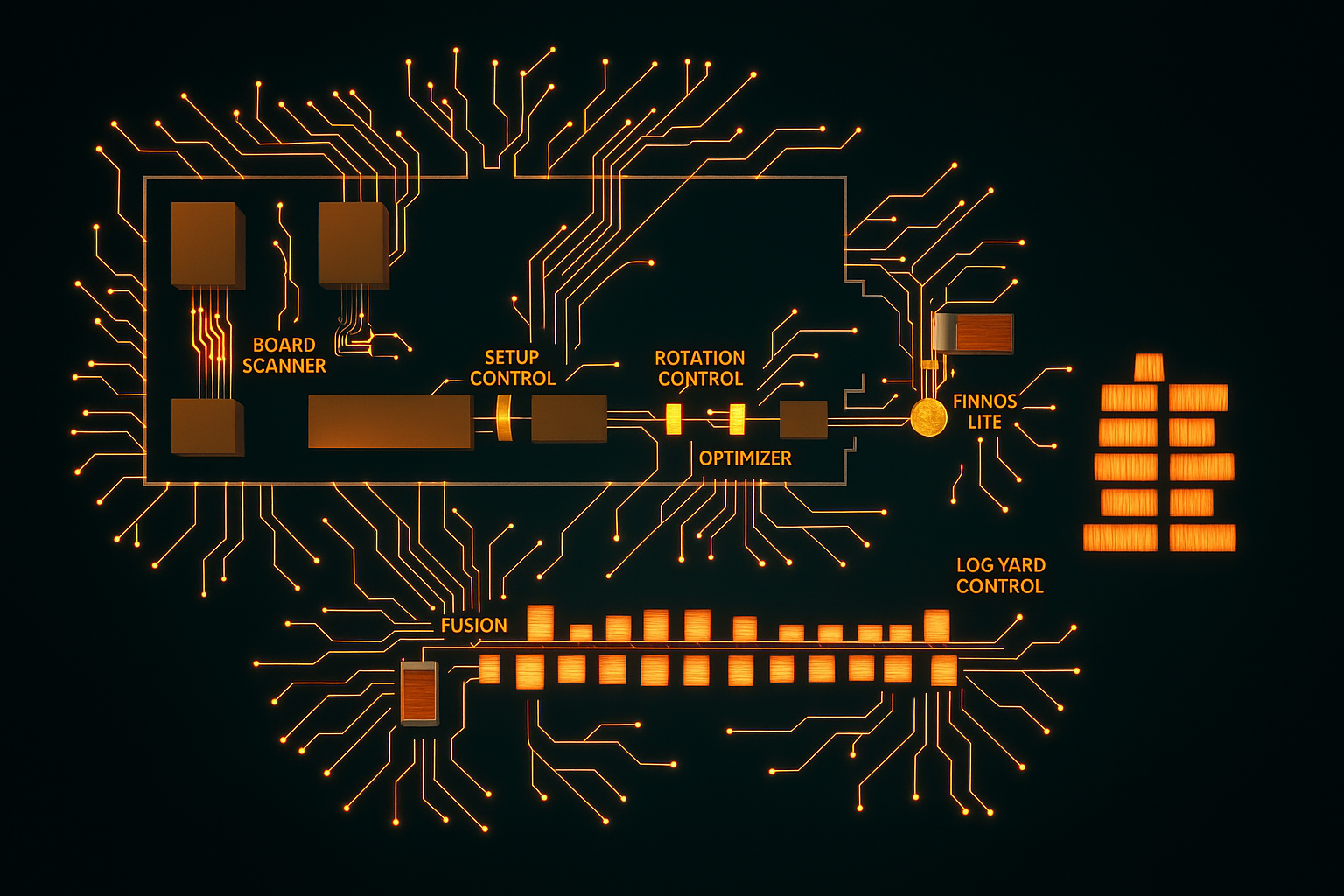

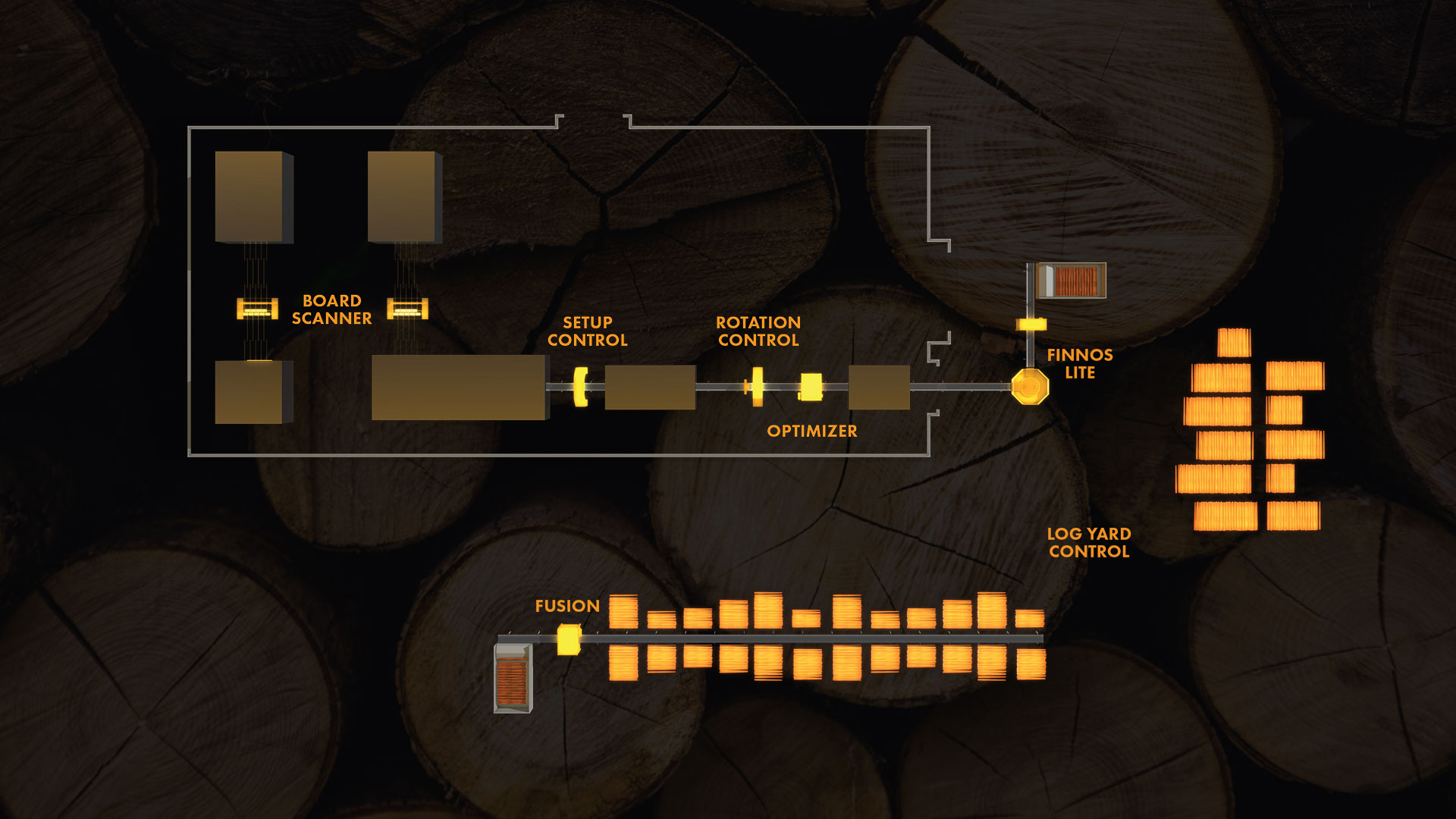

”Finnos’ familiar team and their fast, flexible response to our needs were significant factors in our decision. Experiences with their scanners shared by others in the industry also influenced us. Furthermore, Finnos was able to offer a high-quality solution for log measurement besides the four board scanners” Joki explains regarding the background of the choice.

The collaboration was not limited to a single delivery but has expanded into a comprehensive partnership. Jarmo Joki notes that the close cooperation will continue well into the future: ”The log and board scanner deliveries already agreed upon with Finnos will continue through the summer of 2026.”

Installation in Record Time

In the industrial sector, installation time is a direct deduction from production, making pre-preparation vital. Joki praises how straightforward the transition to the new system was.

”The pre-preparation for the scanner installations and the lifting of conveyors into place shortened the installation time, enabling a fast commissioning process,” says Joki, adding: ”The commissioning phases have proceeded according to plan, even on a tight schedule, and the cooperation has met our expectations.”

Goodbye to Board Turning Devices – Increasing Line Speeds

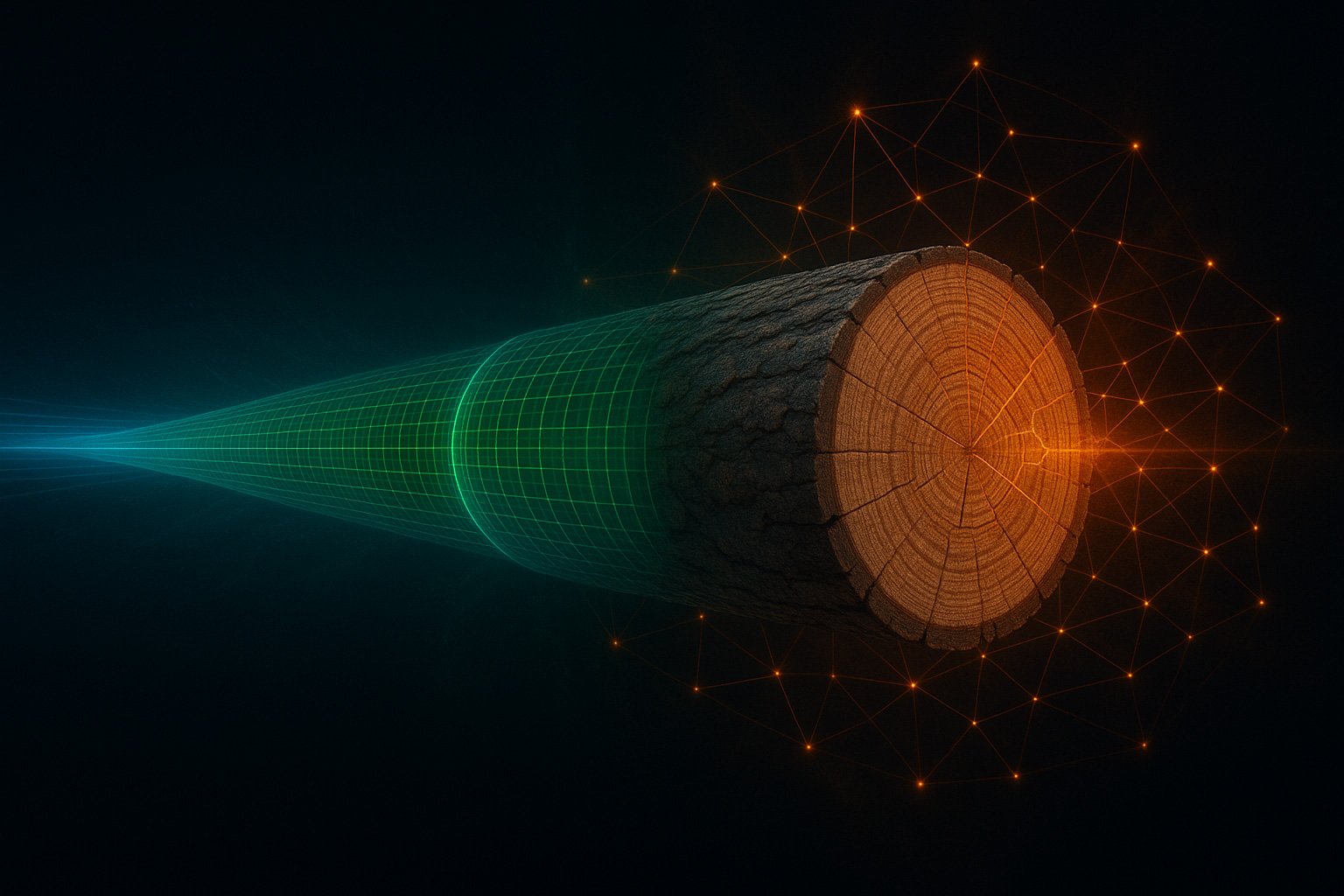

One of the most significant technical leaps was achieved in board sorting. Finnos’ non-turning scanning technology eliminated mechanical bottlenecks from the line.

Jarmo Joki emphasizes that measuring timber pieces without the need for turning has been a major step forward: ”It has enabled us to increase line speeds and has reduced disturbances previously caused by the turning process.”

Faster Reaction Times Through Data

The new system has also received a positive reception from the line operators. The user-friendliness of the system and the accessibility of data have made daily production management easier.

”Real-time data and diagnostics help us monitor and react quickly to changing situations in both production and production planning,” Joki describes. He adds that accessing and analyzing the data has been perceived as easy through the browser-based user interface.

A Partnership That Provides Certainty

While the equipment represents the cutting edge of the industry, Westas particularly values the support that ensures the lines keep running in all situations. Jarmo Joki notes that the 24/7 Helpdesk has provided clarity in handling potential problem situations, thanks to the low threshold for contact.

Finally, Joki reflects on the significance of the investment for the sawmill’s future: ”In the future, we expect the Finnos measurement product family to provide us with valuable additional information about the raw material we use, as well as an increase in profitability as our operations evolve through more precise measurement technology.”

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">

Westas Group and Finnos: Next-Generation Measurement Technology Boosting Exports" width="600" loading="lazy">