When people think of industrial scanners, they often picture lenses, X-rays, and data screens. But what does it actually mean when a scanner is described as “smart”? At Finnos, intelligence isn’t just a buzzword—it’s a layered technology system that analyzes, learns, and responds in real time.

Machine learning: constantly evolving intelligence

Machine learning is the brain behind smart scanning. A Finnos scanner doesn’t just measure logs—it learns from them. Our AI-powered models are trained on millions of logs to identify:

• defect types

• wood quality variations

• density shifts

The result: more accurate analysis, better yield, and fewer errors.

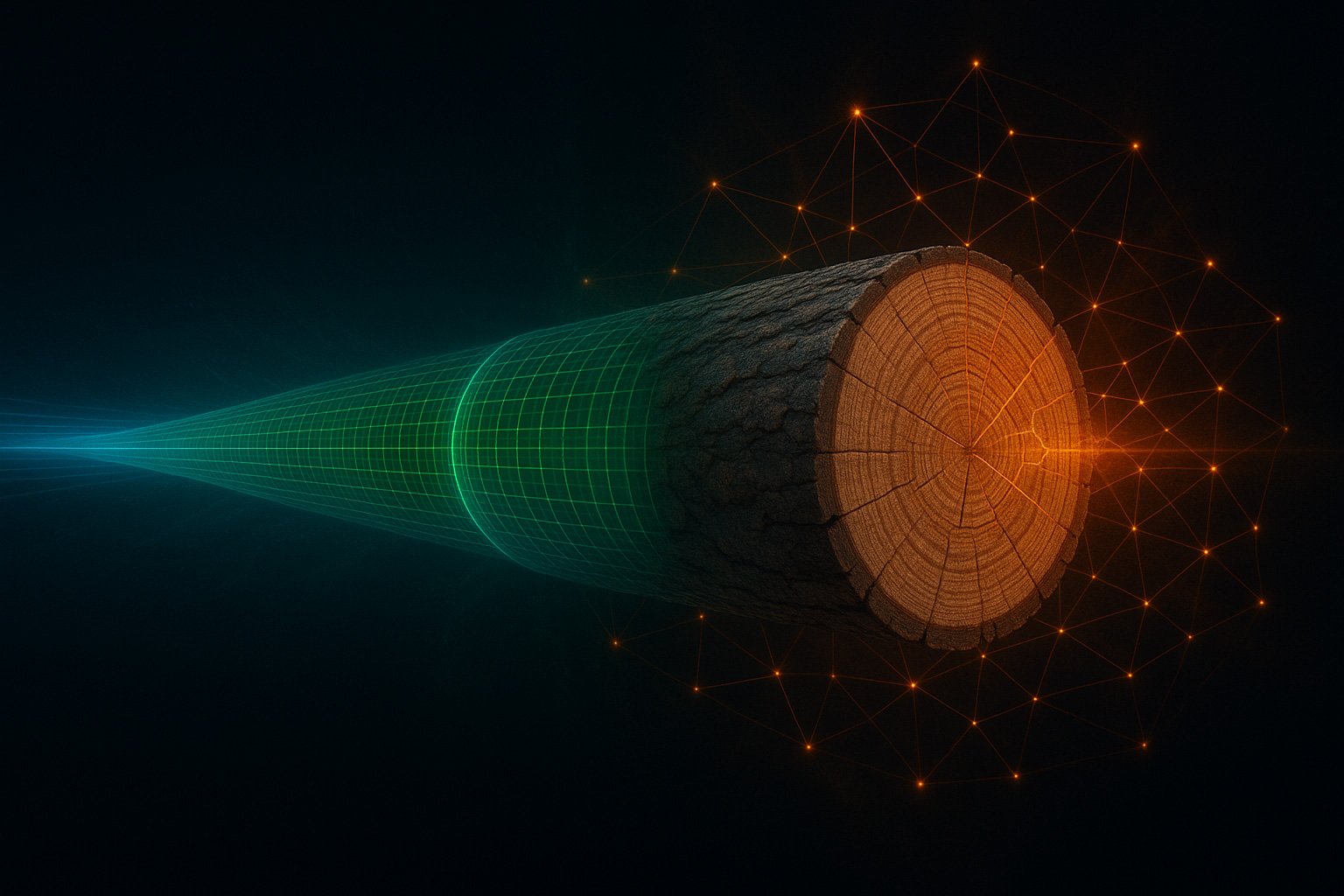

X-ray and CT imaging: going deeper than the surface

Finnos scanners look beneath the surface. X-ray imaging reveals the internal structure of each log:

• density distribution

• heartwood location

• other defects

The latest leap in this technology is Neuro CT—an AI-enhanced computed tomography system that improves or replaces traditional CT stages. It delivers a sharper model of the log’s interior and can be tuned to match the raw material profile of each sawmill’s supply area.

.

Visual recognition: a smart eye for the outside

Visual cameras capture external features such as:

• snow and ice

• barkless area

• color and surface variations

When visual data is combined with X-ray and AI CT, it creates a comprehensive digital fingerprint of each log—crucial for smart processing.

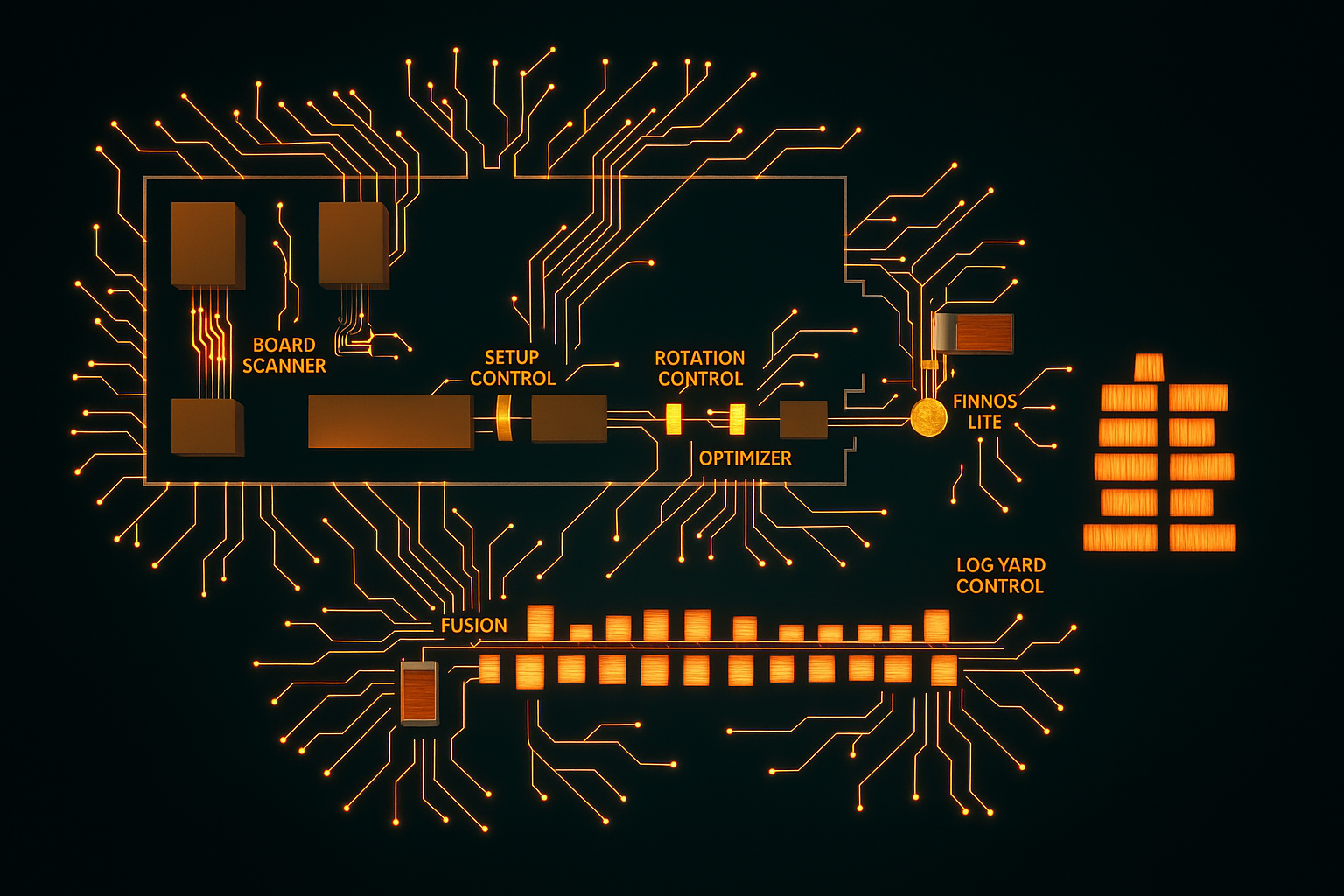

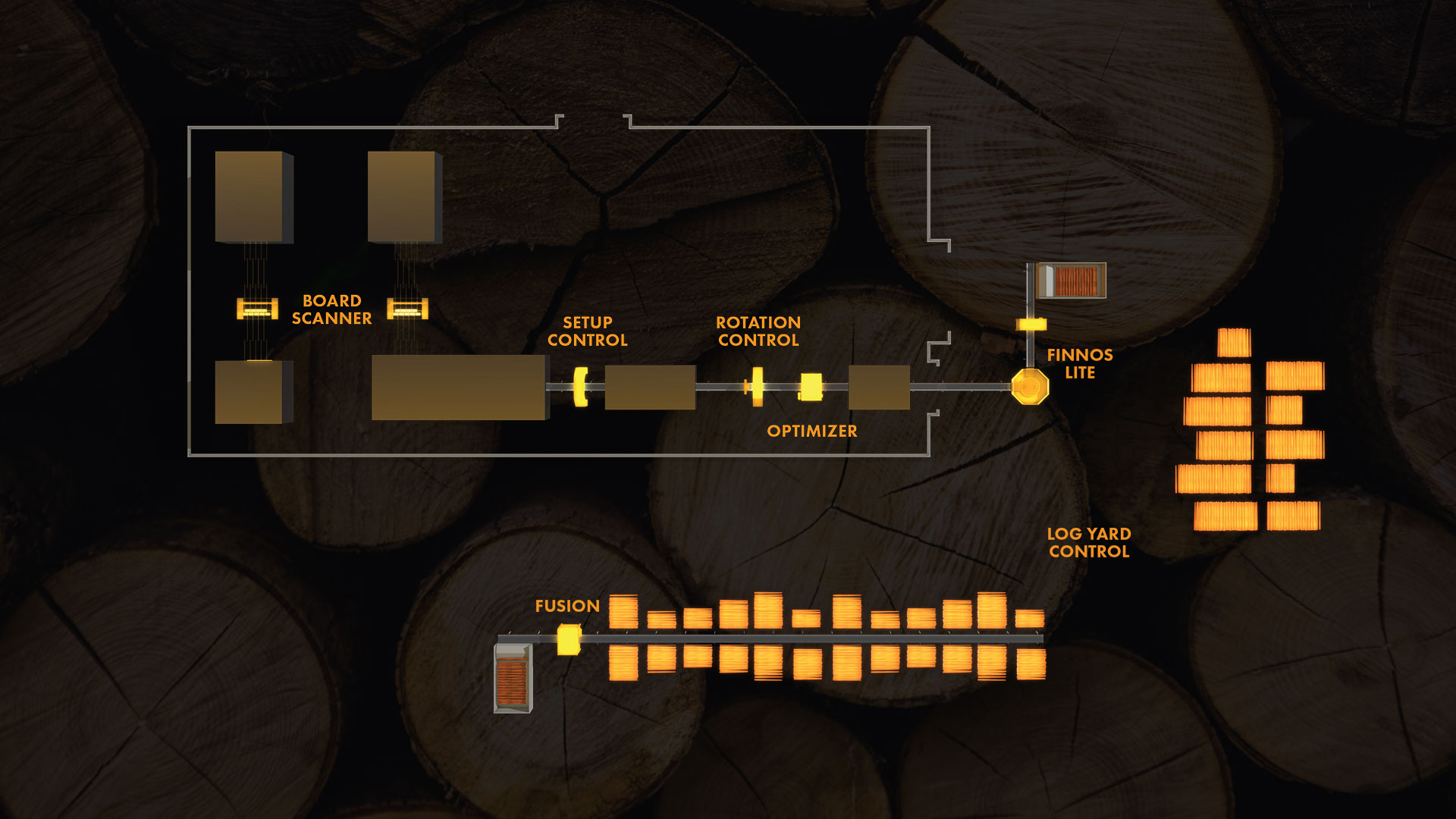

Data integration: from siloed to seamless

A smart scanner doesn’t operate in isolation. It’s part of a larger ecosystem where data must flow across:

• log sorting to cutting pattern optimization

• saw line to board analysis

• reporting to executive decision-making

Finnos systems provide unified data that is available throughout the production chain—empowering smarter, data-driven choices at every level.

Fingerprint technology: optimizing the entire flow

When all scanning and system components are integrated, fingerprint technology becomes possible. It allows individual logs to be tracked throughout the entire production process, enabling:

• identification of bottlenecks

• root cause analysis for quality issues

• targeted process improvements

In practice, this means visualizing and improving the entire sawmill process with unmatched precision.

Summary

Finnos intelligence is more than just AI or sensors. It’s a comprehensive tech stack—combining machine learning, X-ray and AI based CT imaging, visual recognition, real-time data integration, and fingerprint tracking into one seamless system.

This is what makes a scanner smart.

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">

What makes a scanner smart? The technology layers behind Finnos" width="600" loading="lazy">