During #WorldAIWeek, we look beyond buzzwords — and into the heart of real industrial intelligence.

Artificial intelligence is changing how industries operate, from automotive and healthcare to manufacturing and logistics. But few realize how deeply it has already transformed the wood industry.

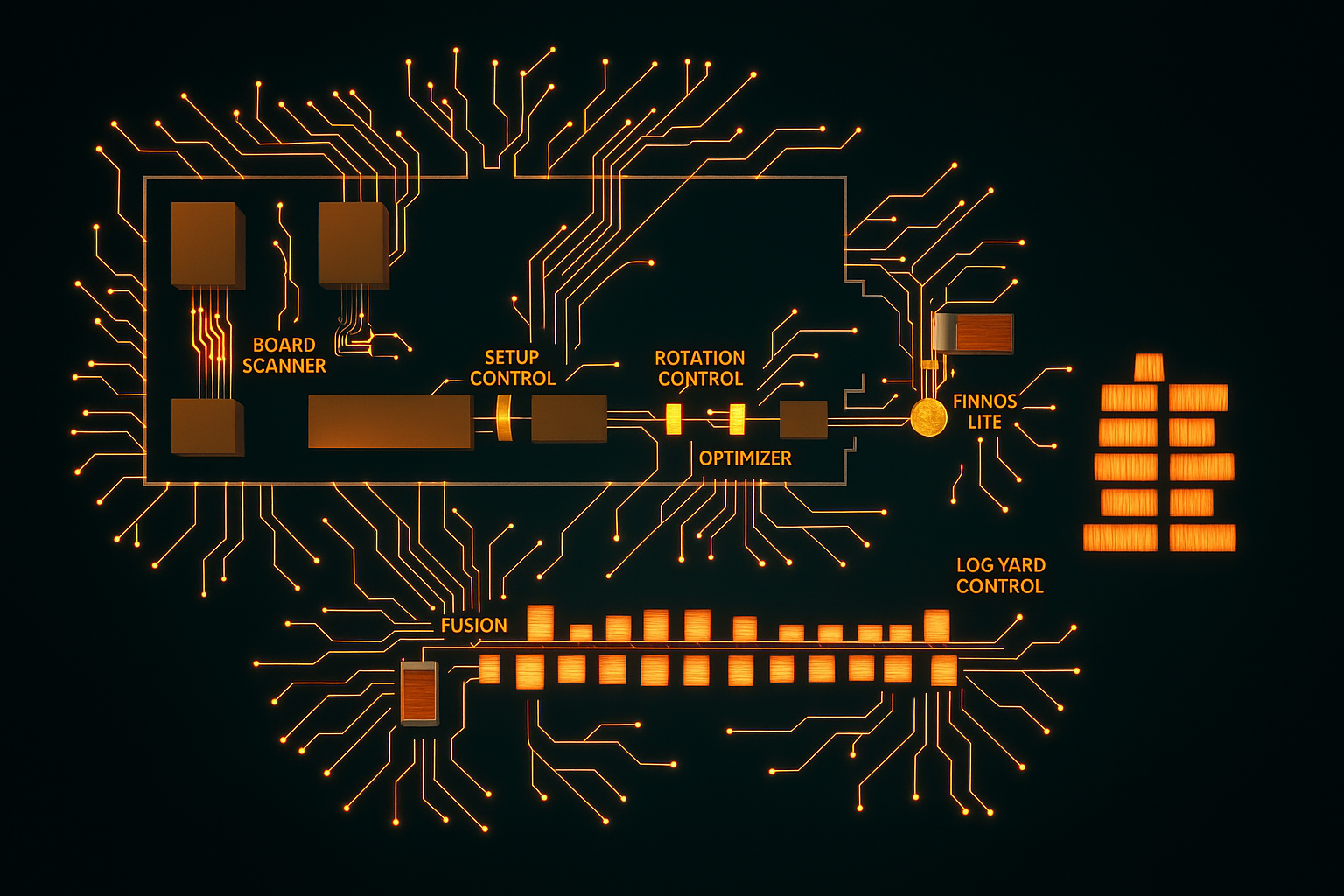

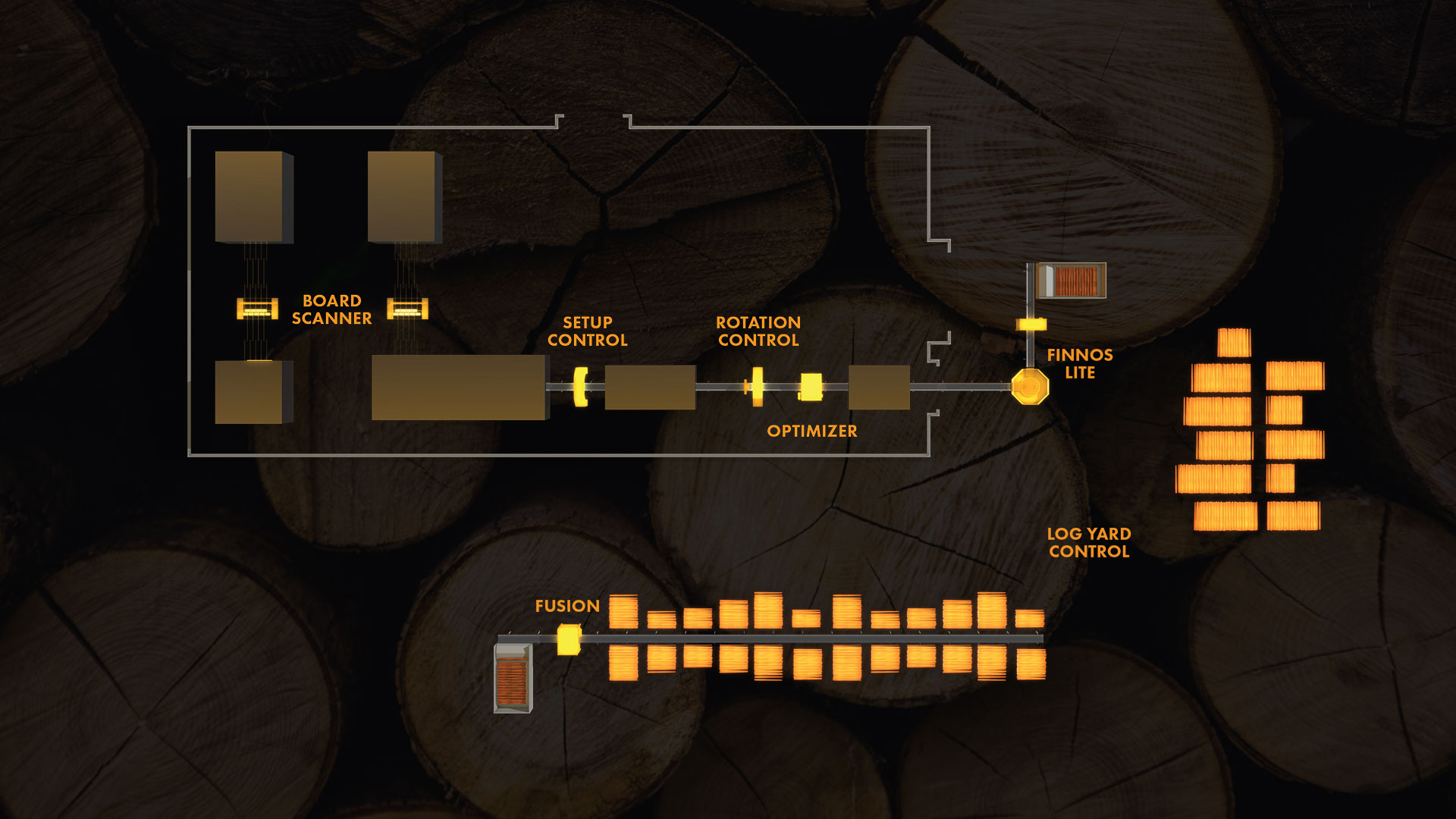

At Finnos, AI is not an experiment. It’s the foundation of our technology — a precision tool that powers every scan, every measurement, and every decision made in a modern sawmill.

Neuro CT – When AI Sees Inside Wood

Every log has a story hidden beneath the surface. With Neuro CT, that story becomes data.

Finnos developed the world’s first neural network-based CT scanner for the wood industry — a system that finds optimal cutting solution for every log in real time.

Using deep learning, Neuro CT identifies internal features such as knots and many other density variations before the first cut is made.

This allows sawmills to:

- Optimize cutting patterns based on internal structure

- Improve yield and product uniformity

By combining imaging hardware and AI algorithms, Neuro CT delivers consistent, data-driven insight directly to the production line — turning what was once invisible into measurable performance.

From Data to Decisions

Industrial AI is only as valuable as the decisions it enables.

Neuro CT doesn’t just collect data; it transforms it into real-time operational intelligence.

Millions of data points from each log are processed and interpreted by deep learning models trained on real sawmill conditions. The output: immediate recommendations that guide automated systems to make the best possible cuts, classifications, and measurements.

This is how Finnos AI bridges the gap between analysis and action.

The result is measurable improvement in yield, throughput, and process reliability — the kind of efficiency that defines a modern smart sawmill.

Precision, Speed, and Reliability in Every Scan

In an environment where milliseconds matter, accuracy cannot be left to chance.

Finnos AI operates directly within the production flow, continuously scanning, analyzing, and feeding back information to the control systems.

By reducing measurement uncertainty and ensuring consistency across shifts, our imaging systems help sawmills reach their full potential day after day.

AI doesn’t replace human expertise — it amplifies it.

Operators gain deeper visibility, maintenance teams get clearer diagnostics, and managers see the complete picture in real time.

Finnos Fusion – The Next Generation of AI-Powered Imaging

While Neuro CT set the standard for intelligent wood scanning, Finnos Fusion takes it even further.

Fusion unites multiple sensor technologies — X-ray, 3D profiling, and RGB imaging — into one integrated AI platform. Advanced algorithms combine these layers into a single digital twin of every log, offering unmatched precision and clarity.

More data. More intelligence. Digested into understandable and useful format for users.

With Fusion, Finnos moves beyond imaging toward true understanding of raw material.

It’s the next step toward a fully connected, automated, and data-driven sawmill — engineered in Finland and built for the global wood industry.

AI as the New Standard for Wood Industry Intelligence

AI in wood processing is no longer a vision of the future — it’s the standard of today’s high-performance production.

By combining physics-based imaging with machine learning, Finnos continues to push the limits of what industrial AI can achieve:

- Greater accuracy and throughput

- Real-time decision automation

- Consistent quality across the entire production chain

As #WorldAIWeek reminds us, the future belongs to industries that can learn, adapt, and make decisions intelligently.

At Finnos, we’re proud to lead that transformation — turning artificial intelligence into real industrial advantage.

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">

AI That Sees Inside Wood – How Finnos Is Redefining Industrial Imaging" width="600" loading="lazy">