To boost the productivity of their sawmill in Squatec, Groupe Lebel has chosen Finnos as their Yield Enhancement Partner (YEP)™️. And for good reasons too, make no mistake.

Reason No. 1 – Advanced log sorting

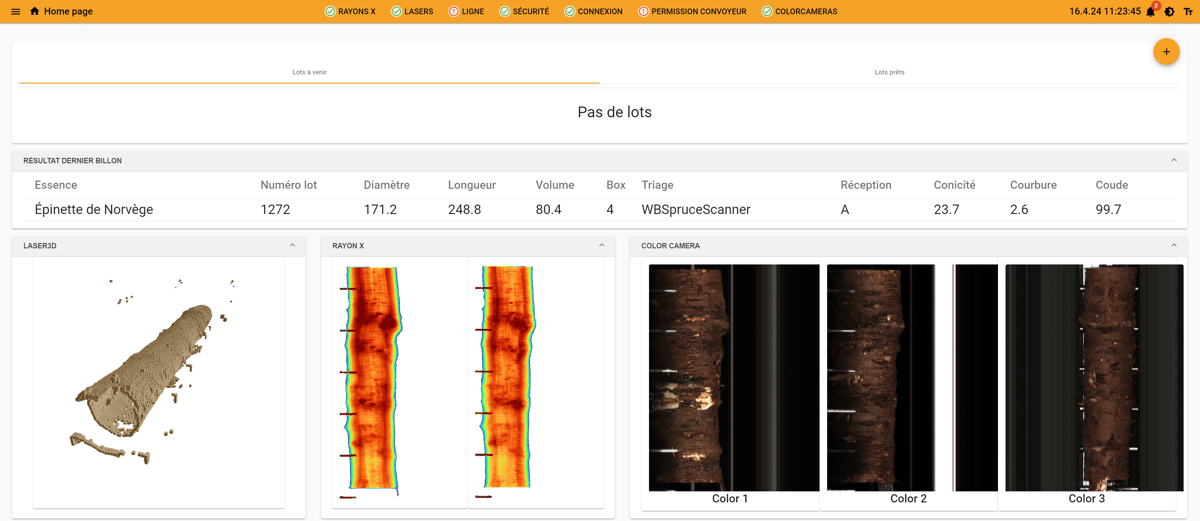

With Finnos, log sorting is so simple, it’s practically automatic. Our scanners analyze all things wood, such as wood species, under bark, geometry, shape, and internal quality of a given log. They also detect foreign objects lodged in the log. Now that we have all the data, our bespoke algorithms take care of the sorting business on their own.

Reason No. 2 – Adapting ad infinitum

Let’s face it. Each project has some hurdles to overcome, and each customer their own challenges. With Groupe Lebel, the challenge was geographical: our R&D happening primarily in Finland we had zero to none previous experience with wood species around the Quebec area. But this is something we had planned for (thanks, our ingenious engineers)! See there’s this small tool called AI that handles the detection of species and many other things as well for us, so the basic principle of recognizing a given species works, we just have to teach the machine with different types of data.

Reason No. 3 – Green. So much green.

Green as in money. Also trees. But mainly money. See the thing is more yield = more money, and Finnos is an expert in maximizing yield: for example our log scanners, equipped with myriad sensors (X-ray, lasers, color cameras, etc.), are capable of measuring the ins and outs of a log e.g. the under bark diameter, knots and rot. This, when met with any log receiving, is a surefire way to acquire material in a more transparent manner, and also to optimize sawing patterns down the line. Which is important to, again, maximize yield.

Reason No. 4 – Cooperation

This is the best part, the fruitiest fruit of our already fruitful customer relationship. It takes the power of something magical called cooperation to streamline the process and ensure a fluent project. And cooperation with Groupe Lebel has been quite smooth indeed thanks to mutual and thorough planning and preparation, both of which were started early on. Due to this early planning phase, our customers get to help us help them customize our scanners to fit their needs. For Groupe Lebel one such customization was rot detection with end cameras, which is under development in – you guessed it – cooperation with the customer.

All in all, we are already seeing promising yield results from the new Groupe Lebel log sorting line, and we’re only just getting started.

Ready to join the revolution? Contact us and get on board!

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

/vida-header.png) Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">

Groupe Lebel aims to new heights with the help of Finnos" width="600" loading="lazy">