Finnos is striving to become a Google in the sawmill industry and has been that already for some time. When fully used, the solutions offered by Finnos is like a search engine, you can ask how you are doing. The newest part of the product range has been the Board Scanner, which improves the data acquisition and productivity of the sawing process.

Not a scanner but a software company

From the point of view of the sawmill industry, Finnos has often been thought of as a meter house. And yes, there are different scanners, alright. However, in practice Finnos is more of a software company.

“A physical measuring device is just a system that produces data. There is nothing magical about it. From the customer's point of view, the magic is in the software, which is intelligent enough to interpret the content of the data” says CTO Juha Alatalo.

As we move along the sawmill process, Finnos has introduced the Board Scanner as the latest measuring device.

What is a board scanner?

The board scanner scans boards from all sides and identifies form the images different types of defects, such as knots, wane, etc. The board scanner is basically a measuring device that scans and grades boards on a transversal conveyor with turning the boards.

“The engineers have not closed the booth to think about the features of the device, but the design started to meet the practical needs of the customer,” describes Jyri Smagin.

A large group of FinScan key personnel is involved in the development of the board scanner. There’s knowledge and experience of tens of years of work behind the team. The developers understand what the scanner is used for at the sawmill to ensure the best possible yield from the customer's point of view.

Finnos understands the needs of the sawmill. The crystallized goal is to achieve the maximum value yield of the sawmill's production. The essential thing about a sawmill is that the right products go to the right bins. No extra or unnecessary trimming is done. Basically, the sawmill gets a better price for better board quality, because the trimming can be minimized with the information produced by the board scanner.

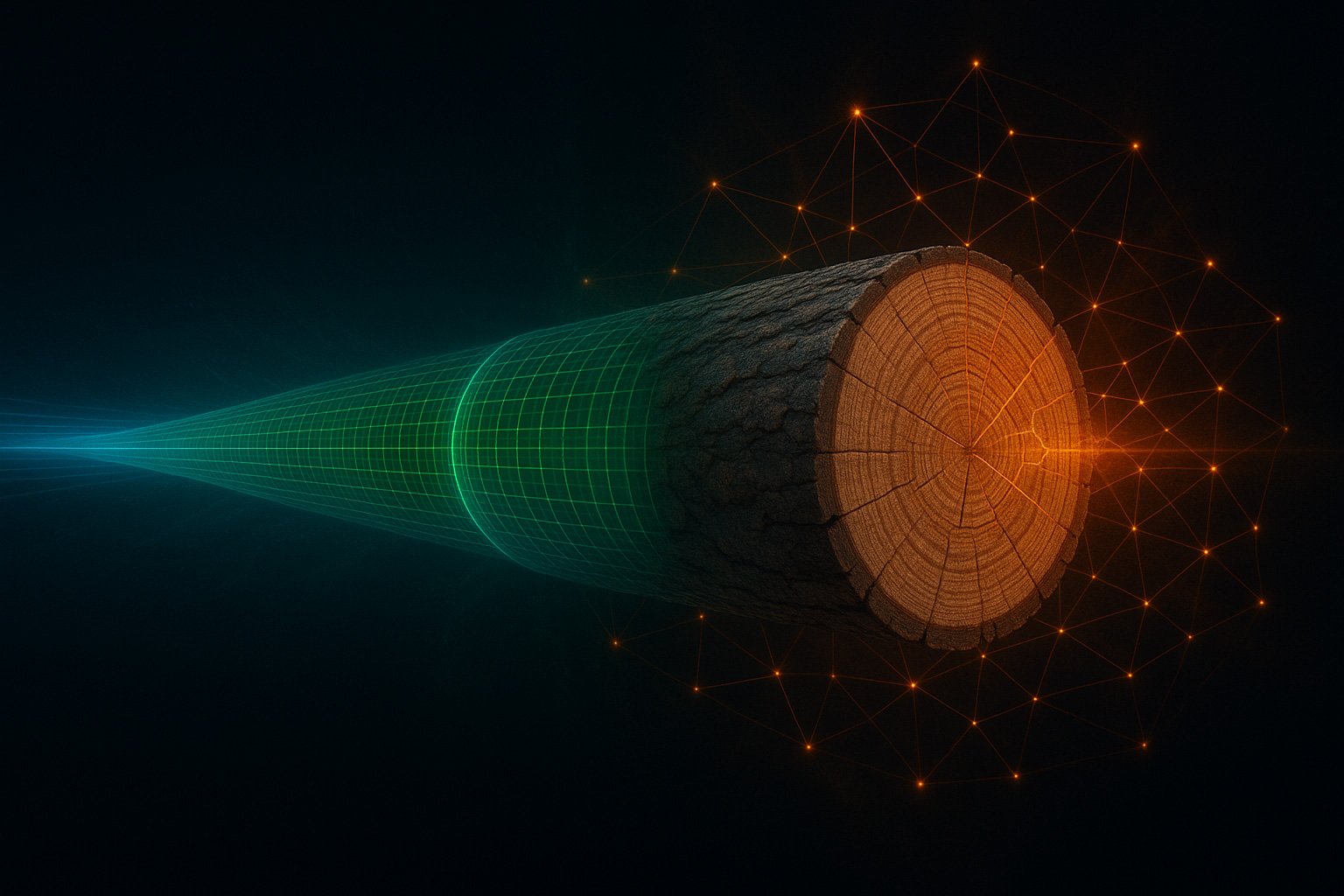

Artificial intelligence behind the scanners

The log and board scanners use extensively AI technology. Artificial intelligence has enabled a software which does the object recognition and image processing. Artificial intelligence detects various defects, such as knots, etc. from that influence the sawing and quality of the products produced by the sawmill.

It's about super-high-tech. Elsewhere in the world, similar artificial intelligence-based software is hardly used in sawmill industry. So far, Finnos has reached the furthest here so far.

Finnos tells how to the sawmill is doing

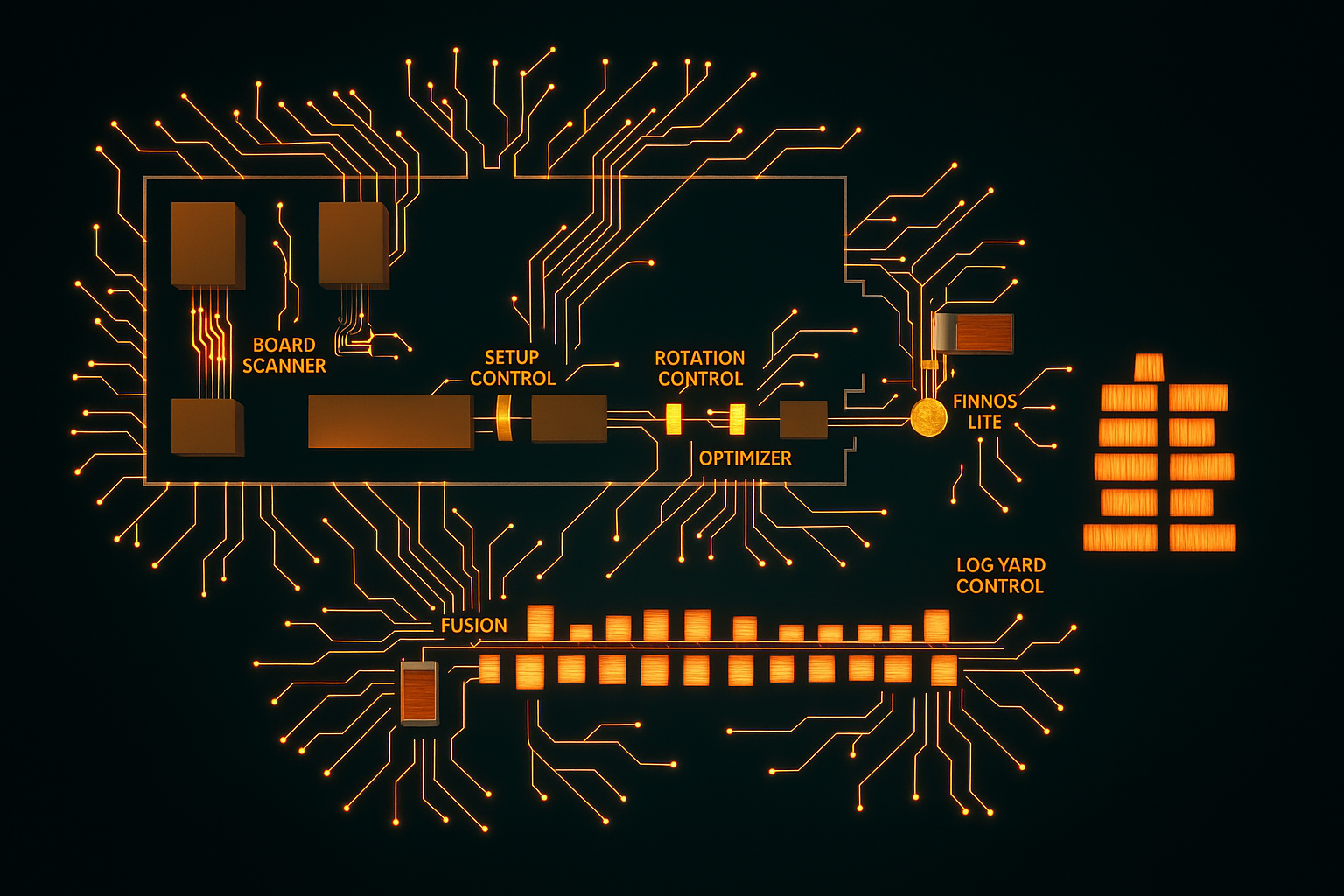

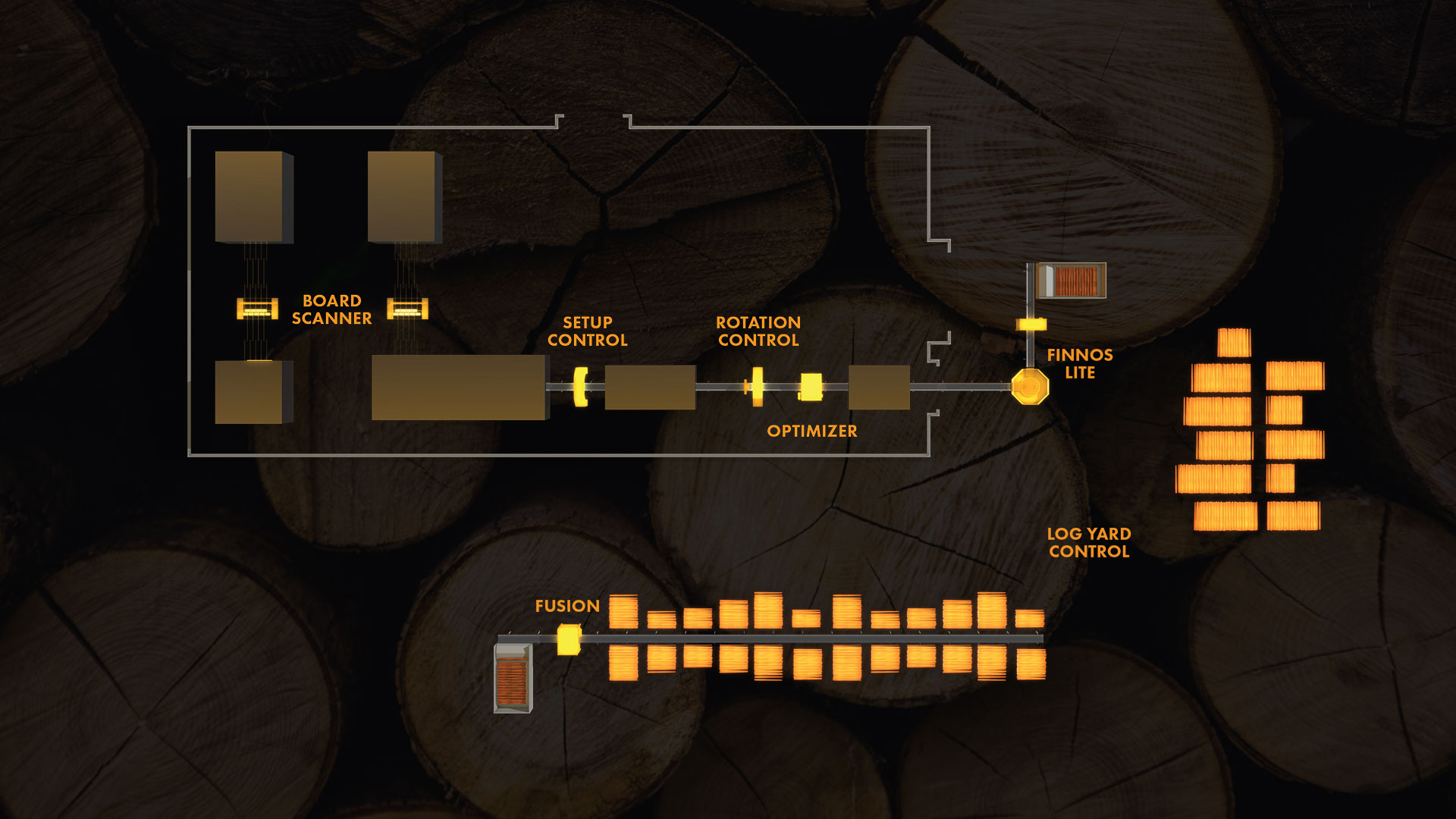

Finnos' strategy is to develop measuring equipment to support the entire sawmill process. At its best, it’s a comprehensive source of information and the best place for the user to see how the saw is really doing.

Finnos Operations software consists of various modules. A customer can take advantage of the parts it needs. If the customer decides to use all the modules in full, there is basically a Google in the sawmill industry that provides up-to-date information on productivity. In a word, Finnos offers an answer to the question of how the sawmill is doing today.

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">

Board Scanner – a gift to the sawmill industry that increases productivity" width="600" loading="lazy">